Auftragssysteme

Als einer der weltweit führenden Anbieter von Laminier- und Beschichtungsanlagen haben unsere innovativen Maschinenkonzepte den Weg zum Erfolg geebnet. Das Lacom-Breitschlitzdüsensystem, das Gravurwalzenverfahren, sowie die Multi-Roller Technologie sind Beispiele für die Umsetzung zukunftsorientierter Ideen mittels modernster Technologien.

Unser Multi-Purpose System bildet dabei die Spitze der Innovation und zeigt zu was die Aumann Lauchheim GmbH in der Lage ist. Wir orientieren uns dabei konsequent an den Anforderungen des Marktes und erfahrener Kunden. Sie sind fester Bestandteil bei der permanenten Weiterentwicklung unserer Produkte.

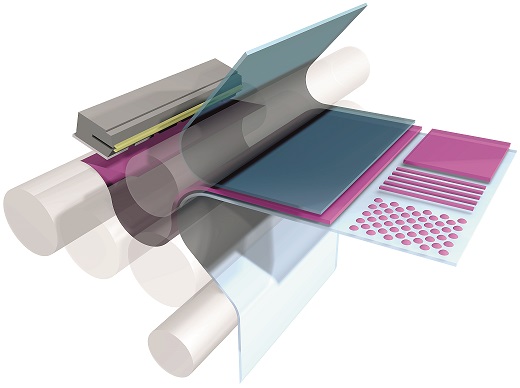

MPBL- Beschichtungs- und Laminierwerk

– Kombinierter Gravur- u. Mehrwalzen Auftragskopf

– schnelle Systemumstellung ohne mechanischen Umbau

– Punktbeschichtung

– vollflächige Beschichtungen

– O.C.S. (Open Coating Struktur)

– Herstellung von Duplex- und Triplexlaminaten mittels

thermoplastischen und reaktiven Hotmelt Klebstoffsystemen

– weicher textiler Griff der Laminate

– geringer Energieverbrauch

Das Multi Purpose Hotmelt Laminier- und Beschichtungswerk ist vielseitig einsetzbar. Durch die Kombination eines Gravurwalzensystem mit einem Mehrwalzensystem entsteht eine noch nie dagewesene Flexibilität in der Produktion, die es dem Anwender ermöglicht, schnell und unkompliziert zwischen den verschiedenen Auftragssystemen zu wechseln, ohne dabei längere Produktionsausfälle in kauf nehmen zu müssen. Diese von Aumann entwickelte Technologie ist weltweit patentiert und bis heute einzigartig.

MRBL – Beschichtungs- und Laminierwerk

– vollflächige Beschichtungen von Substraten

– O.C.S. (Open Coating Struktur)

– Herstellung von Duplex- und Triplexlaminaten mittels

thermoplastischen und reaktiven Hotmelt Klebstoffsystemen

– atmungsaktive Laminate und vollflächige Beschichtungen

– textiler Griff der Laminate

– geringer Energieverbrauch

Das Multi-Roller Beschichtungs- und Laminierwerk dient unter anderem zur vollflächigen Beschichtung von verschiedensten Materialien und sorgt für eine extrem hohe Verbundfestigkeit, insbesondere bei Produkten, die sehr hohen mechanischen und thermischen Belastungen im täglichen Gebrauch ausgesetzt sind. Durch eine gezielte Steuerung der einzelnen Walzen kann mit diesem Auftragskopf ebenfalls ein atmungsaktives Laminat hergestellt werden.

DBL – Beschichtungs – und Laminierwerk

– vollflächige Beschichtung

– O.C.S. (Open Coating Struktur)

– Herstellung von Duplex- und Triplexlaminaten mittels thermoplastischen und reaktiven Hotmelt Klebstoffsystemen

– atmungsaktive Laminate

– weicher, textiler Griff der Laminate

– geschlossenes Applikationssystem

– kontaktarmer Klebstoffauftrag

– Verarbeitung hochviskoser Medien

– hohe Produktionsgeschwindigkeiten

Die Breitschlitzdüse ist vielseitig einsetzbar. Neben der vollflächigen Beschichtung kann auch mit einer Open Coating Struktur gearbeitet werden, was die Herstellung von atmungsaktiven Laminaten ermöglicht.

Der Einsatz der Düsentechnologie erlaubt die zuverlässige Applikation von hochviskosen Medien bei sehr hohen Produktionsgeschwindigkeiten.